Thermal Energy Storage (TES)

Industrial-Scale Energy Storage for Heat & Cooling

-50°C to 250°C | 20–30+ Year Life | 95% Round Trip | No DNSP Approvals

Electrifying heat is simple.

Running it reliably and cost-effectively is not — unless you store energy.

Thermal Energy Storage (TES) enables factories to shift heat and cooling loads away from peak demand, stabilise heat pump operation, capture waste heat, and run through grid disturbances without production loss.

We deploy high-density Phase Change Material (PCM) storage, engineered for industrial thermal duty. TES integrates into process loops like any mechanical asset — it does not behave like a battery system.

No export limit.

No DNSP negotiation.

No degradation curve.

TES is infrastructure-level storage for heat & cooling.

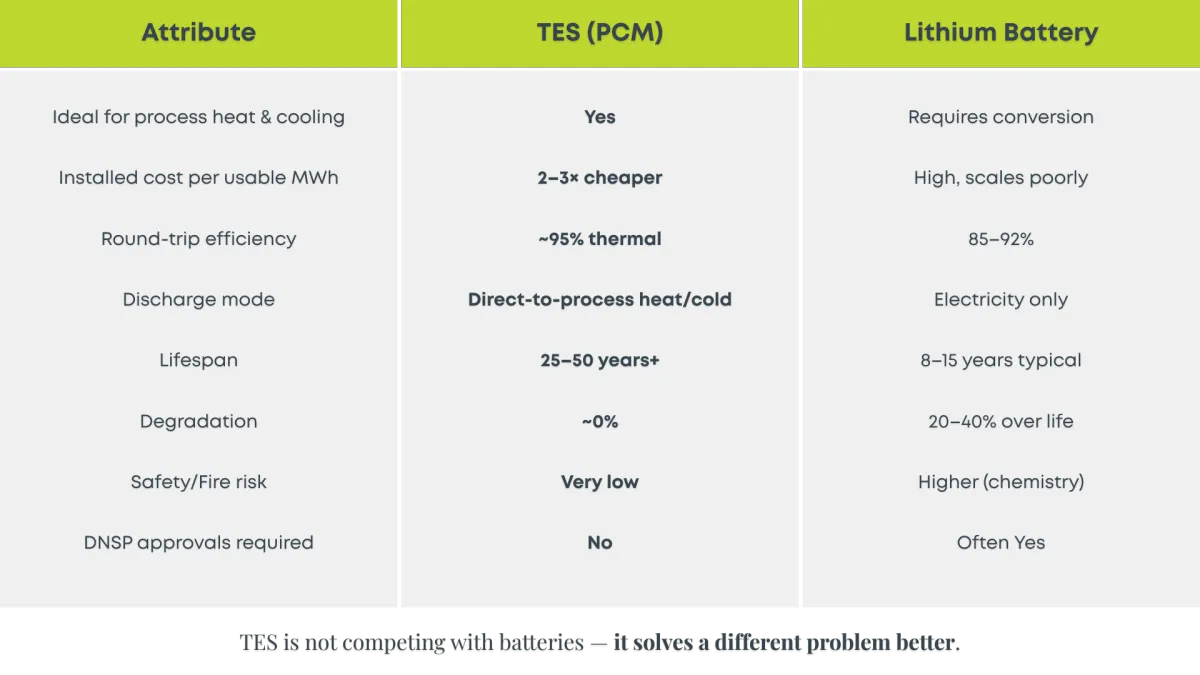

Why TES Instead of Batteries?

How Phase Change Storage Works

Water freezing at 0°C stores more energy than heating water from 0°C to 80°C.

Why? Latent heat of fusion.

We apply the same physics using engineered PCM salts and composites.

When energy is added, the PCM changes phase and absorbs large amounts of heat with minimal temperature rise. When energy is needed, the material solidifies and releases that stored energy on demand, instantly.

Operating ranges:

-50°C → 250°C industrial envelope

Storage density:

Up to 4–10× higher than sensible hot water tanks

Response time:

Immediate heat/cold dispatch

Footprint & Format

Modular blocks or tank banks

Hot or cold storage options

Can be containerised for rapid install

Typical 1 MWh thermal ≈ 2–10 m³ footprint depending on temperature range

Example:

20 MWh TES = ~1 × 40ft container equivalent

Where TES Fits

High-value use cases where boilers & chillers cycle heavily:

Meat & protein processing

Dairy, cheese, yoghurt

Breweries & wineries

Refrigeration/cold stores

Rendering/tallow

CIP & sanitation

If heat pumps alone electrify a site, TES allows us to electrify it reliably.

What TES Enables

Run heat pumps continuously at maximum SCOP

Entirely remove peak boiler operation

Shift load from peak to off-peak electricity

Firm industrial heat & cooling 24/7

Boiler-free operation when integrated with MVR

Peak load clipping without electrical batteries

Ride through grid disturbances (resilience)

TES turns renewable electricity into firm industrial heat.

Performance & Integration

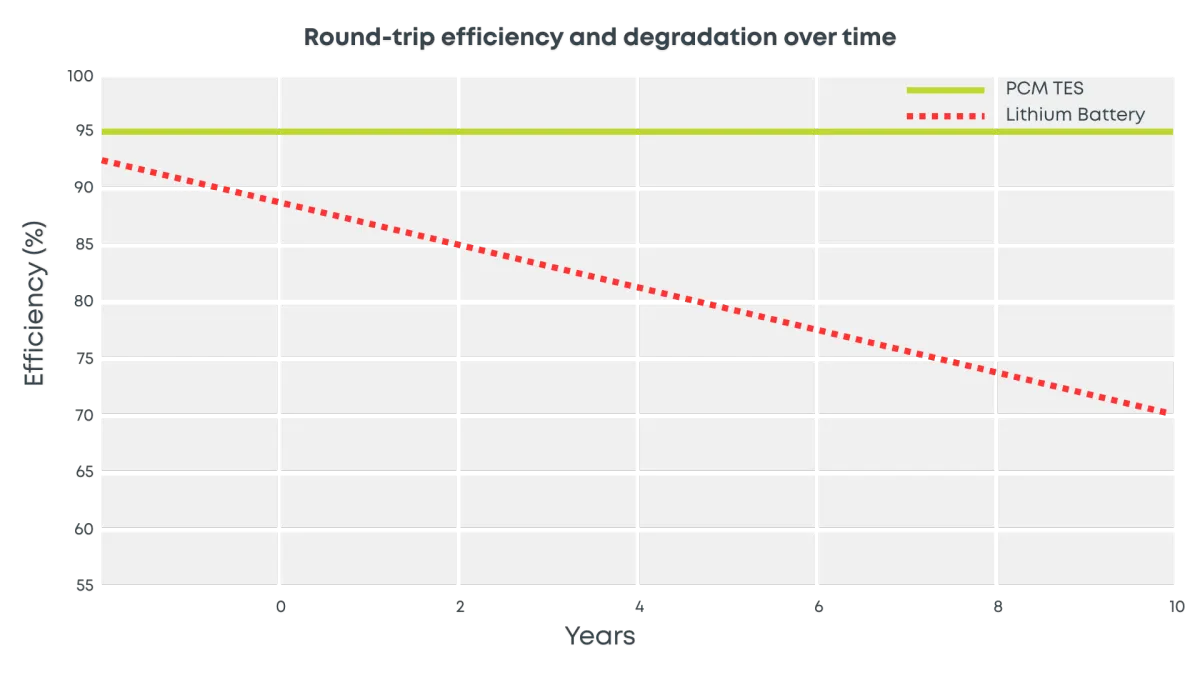

Round-trip thermal efficiency: ~95%

Discharge depth: 100% usable

Operating life: 25–50+ years

Charge via: heat pump, WHR, MVR, surplus refrigeration

Discharge to: hot water, process heat, chilled glycol, brine

We exclusively use phase change storage — not water tanks — because density matters in factories.

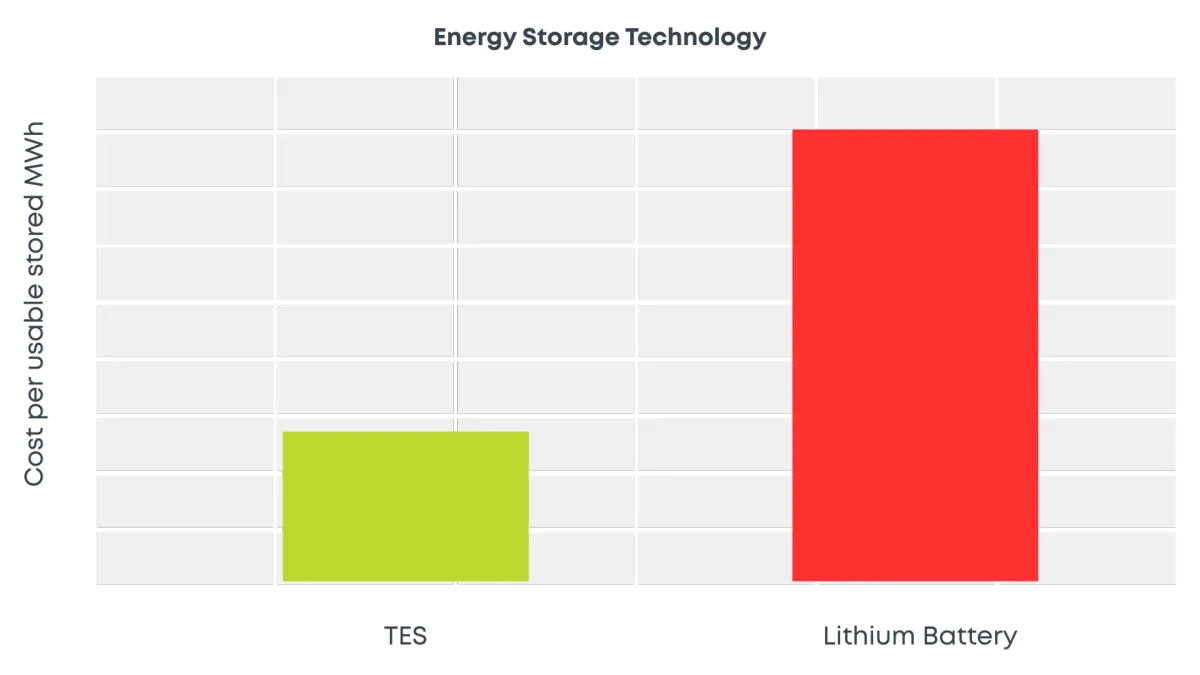

Storage Economics

Installed and commissioned, TES typically delivers:

2–3× lower $/MWh delivered heat than lithium batteries

…and outlives them by a factor of 2–3.

Efficiency & Lifecycle

Unlike batteries, thermal storage does not degrade over time.

Resilience & Reliability

No fire risk like Li-ion systems

No complex grid approvals

Mechanical infrastructure, not electronics

Designed for 24/7 industrial cycling

Minimal maintenance

Works N+1 with heat pumps

TES removes the last argument for keeping gas.

Why We Deploy TES

Because high efficiency heat pumps are most powerful when backed by storage.

Base-load operation increases lifespan, reduces compressor cycling,

and increases system SCOP dramatically.

TES + Heat Pump + MVR =

Boiler replacement with permanent decarbonisation.