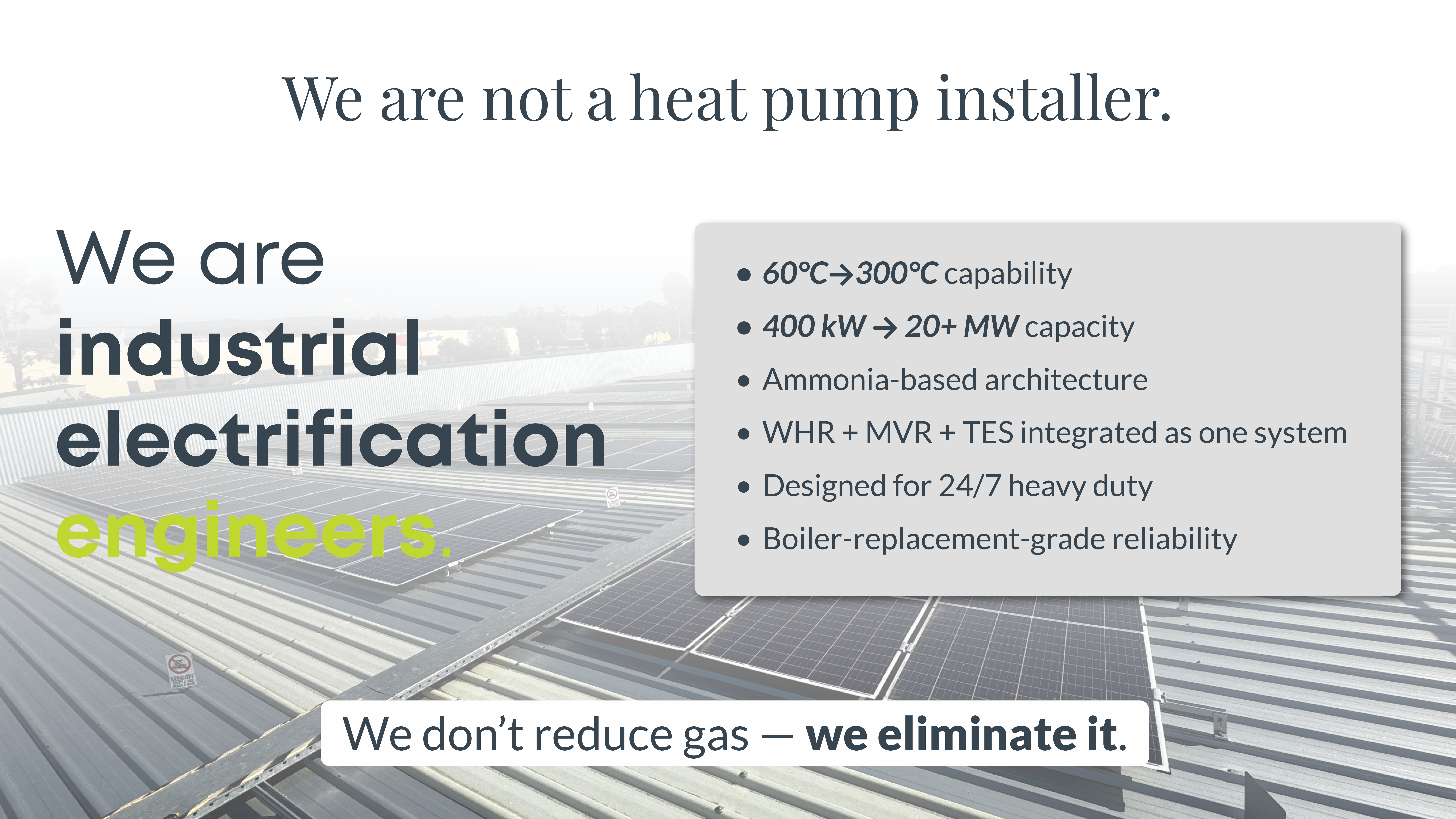

Industrial Heat Pumps & Thermal Electrification

Megawatt-Scale Process Heat — 60°C to 300°C — Engineered to Replace Gas

We electrify process heat for heavy industry.

Our ammonia-based industrial heat pump systems generate hot water, high-temperature heat and steam-equivalent output without combustion, while recovering waste heat and reducing energy consumption by 3–8× vs gas boilers.

This is not HVAC — this is industrial thermal infrastructure.

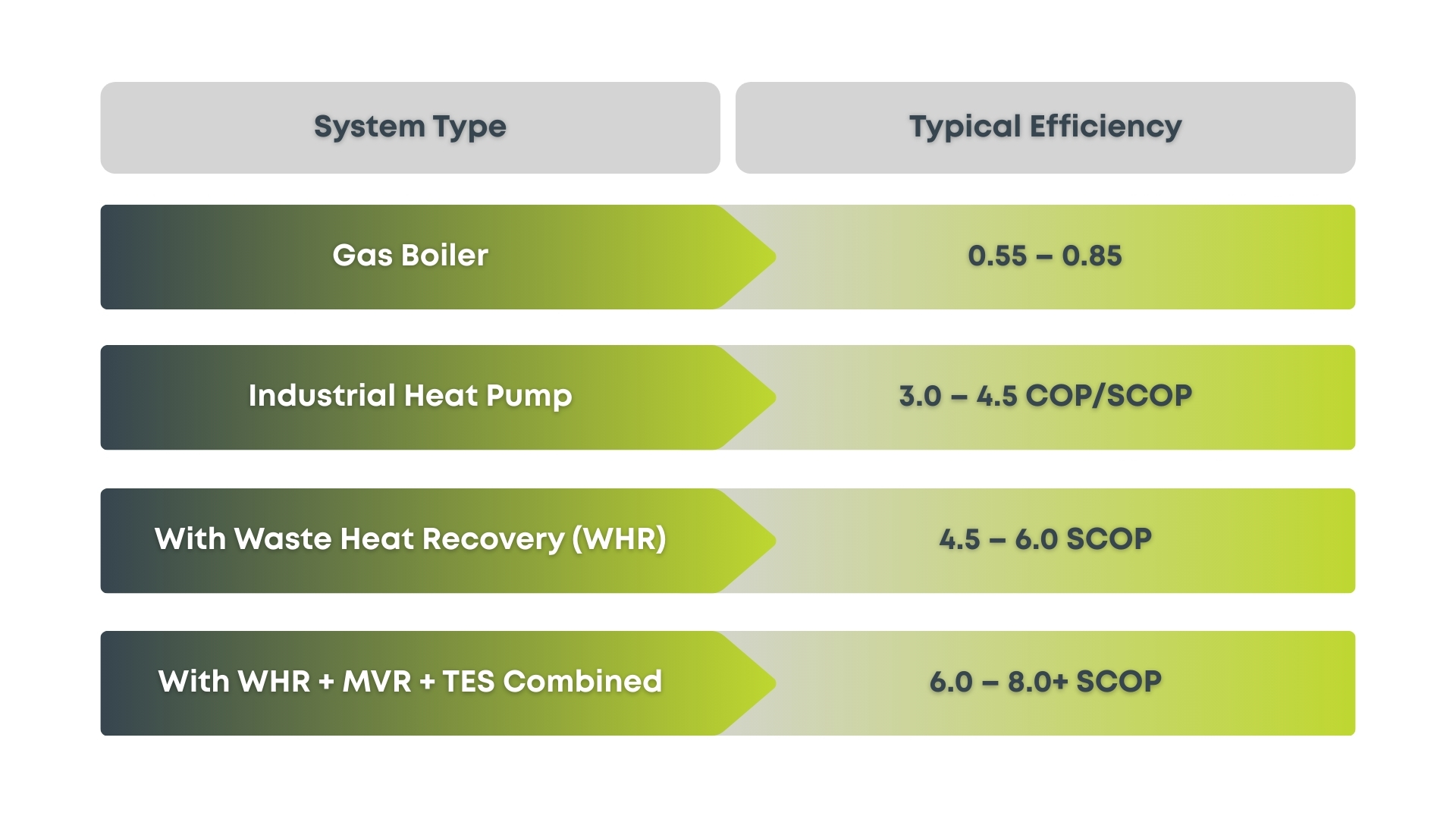

Why Electrify Heat?

Gas boilers are limited by combustion efficiency (~55–85%).

Heat pumps are driven by thermodynamics — they move heat instead of burning fuel.

1 unit of electricity → 3–8 units of usable heat.

Combustion can never do that.

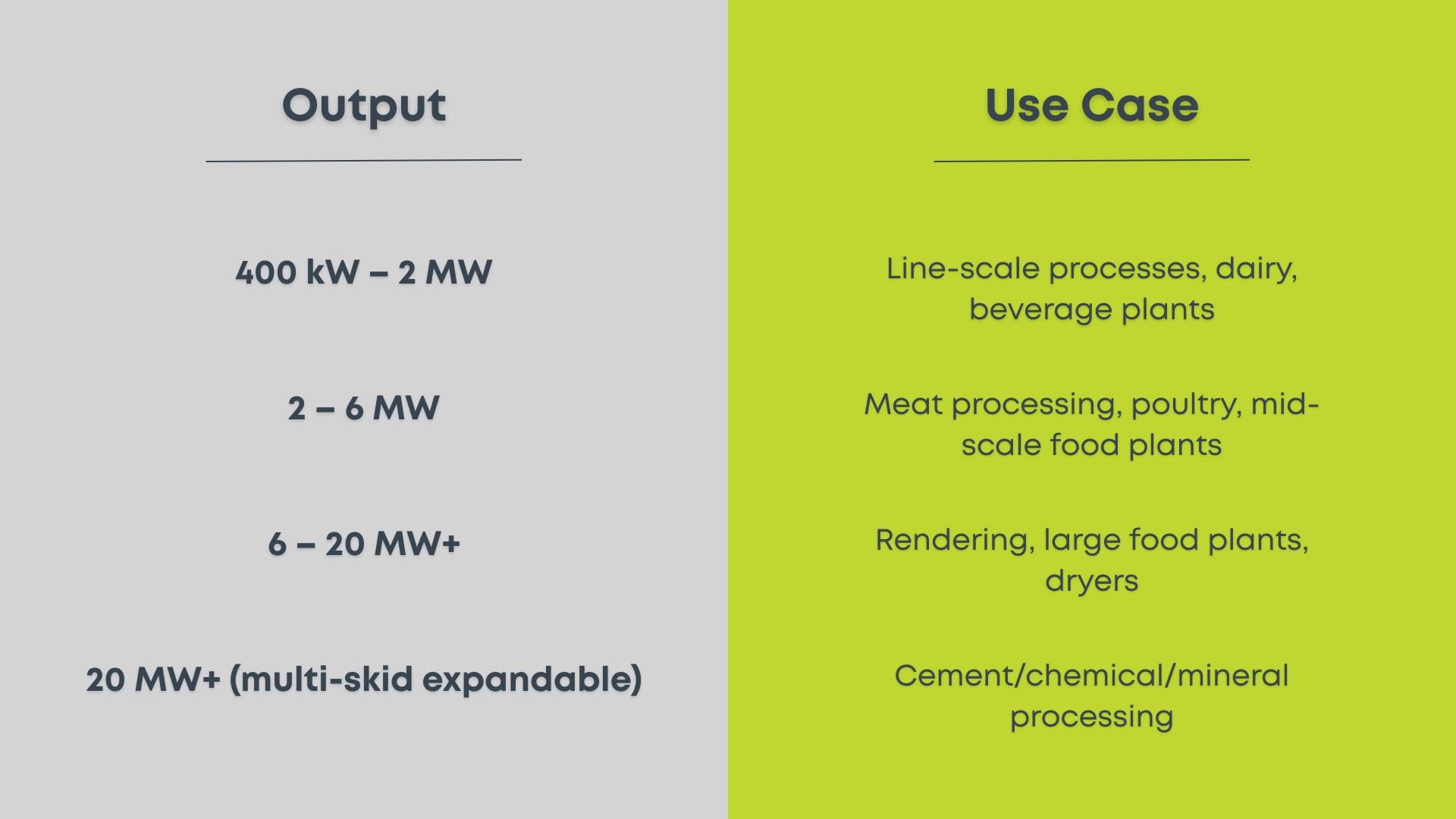

Heat Pump Temperature & Power Capability

Temperature Output:

60–120°C hot water, sanitation, CIP

120–200°C pasteurisation, cooking, rendering

200–250°C steam replacement & high-grade heat

Up to 300°C staged MVR-assisted systems

Plant size:

We design systems large enough to replace boilers, not supplement them.

How an Industrial Heat Pump Works

Moving heat is cheaper and more efficient than burning fuel.

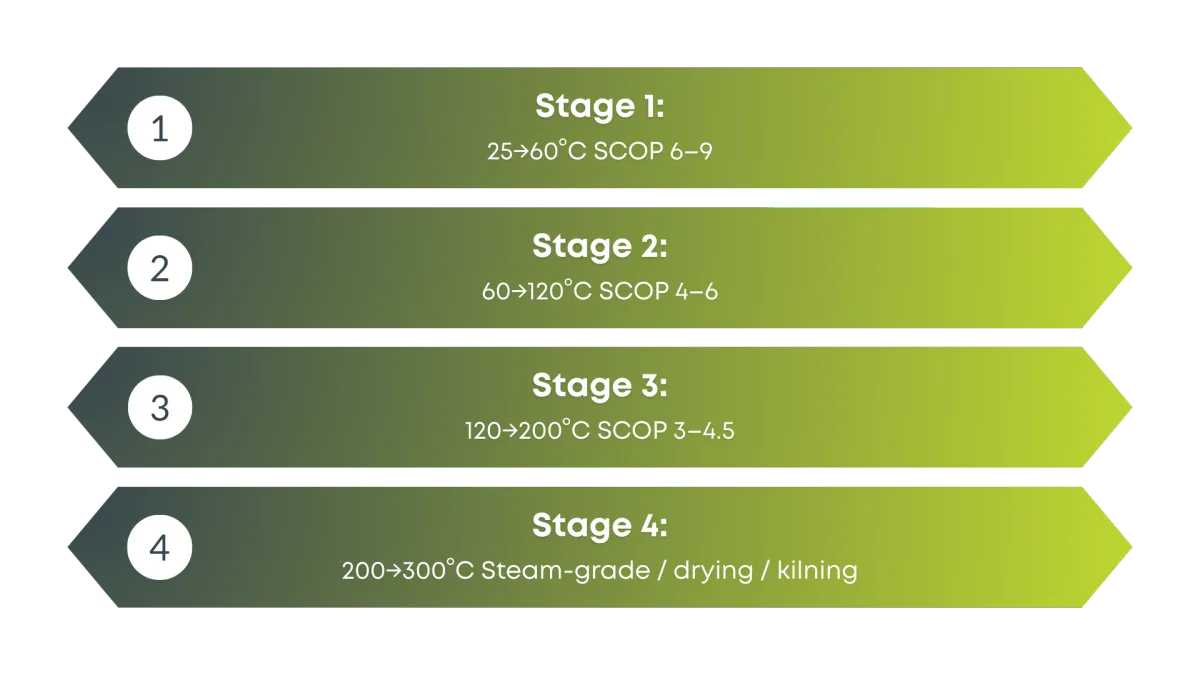

Multi-Stage High Temperature Architecture (to 300°C)

Trying to jump from 25°C to 200–300°C in one step kills efficiency.

We stage temperature lifts for thermodynamic gain:

Multiple smaller lifts outperform one large lift —

This is how high-temperature electrification becomes viable.

Waste Heat Recovery (WHR)

We reclaim heat sources your site already generates:

Refrigeration condensing heat

Hot glycol/brine returns

Cook/smoke exhaust

Pasteuriser discharge

Boiler blowdown

Warm effluent streams

Recovered heat becomes free fuel for the compressor.

Mechanical Vapour Recompression (MVR)

High-temperature vapour contains latent energy.

MVR recovers, compresses and returns it as usable heat.

Ideal for:

Rendering & tallow plants

Smokehouses & cook rooms

Dryers & dehydrators

Milk evaporation & concentration

Distillation and fermentation

Starch/sugar drying

Chemical & concrete heating processes

MVR is the gateway to 200–300°C electrification.

Thermal Energy Storage (TES)

Heat pumps like stability.

Production lines have peaks & valleys. TES bridges them.

TES enables:

Off-peak operation

Shift buffering

Smaller heat pump sizing

Maintenance continuity

Flat energy curves

Massive SCOP uplift

TES is not optional — it is the SCOP multiplier.

Controls & Redundancy Architecture

Industrial uptime is non-negotiable.

We design:

Multi-compressor parallel loops

N+1 redundancy pathways

Independent staging circuits

SCADA/PLC integration

Remote optimisation

TES-assisted continuity

A boiler crack = total outage.

A heat pump circuit trip = reduced output, not shutdown.

Industries We Electrify

Food, Meat & Agri-Processing

Lamb, beef, poultry, dairy, cheese, processing lines, smokehouses, rendering, drying.

Beverage & Fermentation

Breweries, wineries, distillation, carbonation, pasteurisation.

Cold Storage + Industrial Refrigeration

WHR integration delivers highest SCOP uplift.

Manufacturing & Heavy Industry

• Concrete curing

• Cement drying & pre-heat

• Asphalt plant heating

• Chemical reactors

• Paper/pulp processes

• Textile dyeing & drying

• Kilning support & pre-heat

• Process steam replacement up to 300°C

If it burns gas to make heat — it is electrifiable.

Why Choose Us