Controls & Industrial Energy Management

The Intelligence Layer Behind Electrified Heat

PLC-Controlled | SCADA Monitored | AI-Assisted Optimisation | OEM Agnostic

Heat pumps, TES, solar and batteries only become powerful when they work as a coordinated energy ecosystem. Our control platform is what synchronises them — prioritising efficiency, uptime, safety and cost.

We design and deploy full industrial control architecture, including PLC logic, SCADA dashboards, sensor integration and automated load scheduling.

This is where decarbonisation becomes operational reality.

What Our Controls Do

Balance heat pump supply vs process demand

Charge/discharge TES automatically

Maintain target temperatures without cycling losses

Respond to production schedules and shift patterns

Prioritise solar generation when available

Control battery dispatch dynamically

Optimise around tariffs, peak periods & wholesale pricing

Fail-safe logic with N+1 redundancy pathways

Interface with existing plant control infrastructure

Your plant becomes self-optimising rather than operator-dependent.

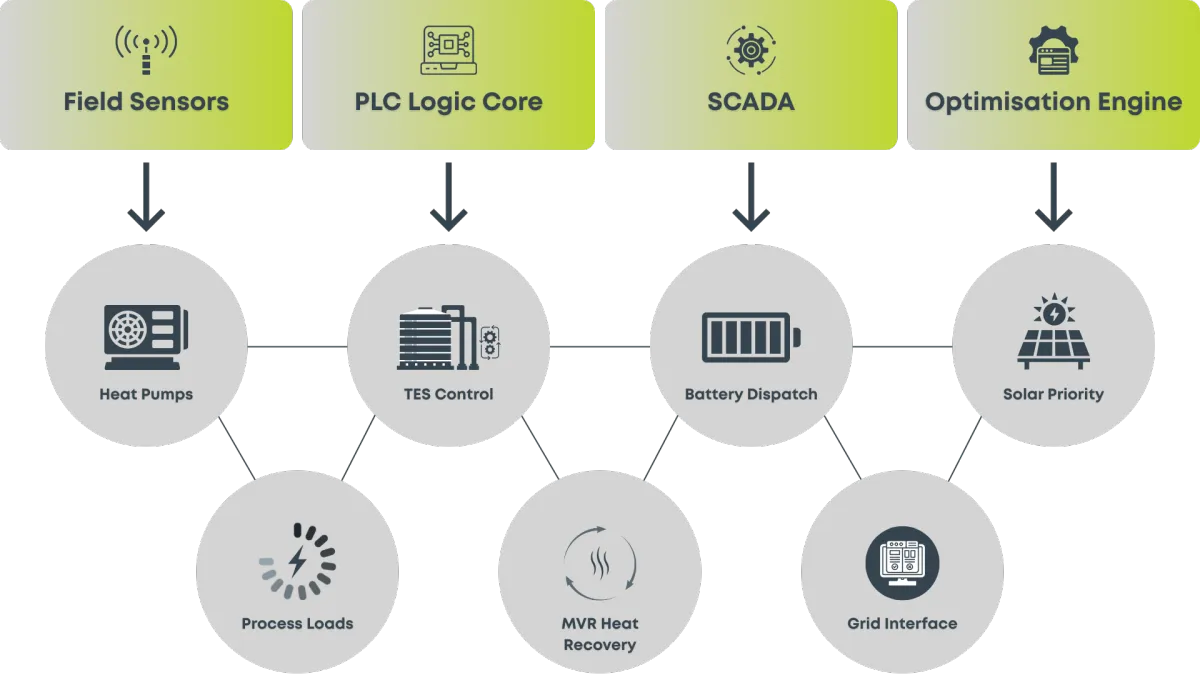

System Architecture

Everything speaks one language — reliably, continuously, safely.

Features

Process temperature & load tracking

Real-time efficiency optimisation

Demand limiting & peak shaving

Heat/cool curve prediction using machine learning

Automated thermal scheduling

Fault tolerance & safe-mode fallback

Remote monitoring and alarms

Multi-site deployment support

Goal: Maximum SCOP. Minimum operator input. Maximum uptime.

Why Controls Matter More Than Hardware

Anyone can buy equipment.

Only orchestration delivers performance.

Without smart control: oversizing, short cycling, inefficiency

With orchestration: smooth baseload operation & high SCOP

Thermal storage works only when managed predictively

Solar value multiplies when heat/cooling schedules align

Battery revenue unlocks with correct dispatch logic

Controls turn equipment into a cohesive decarbonisation plant.

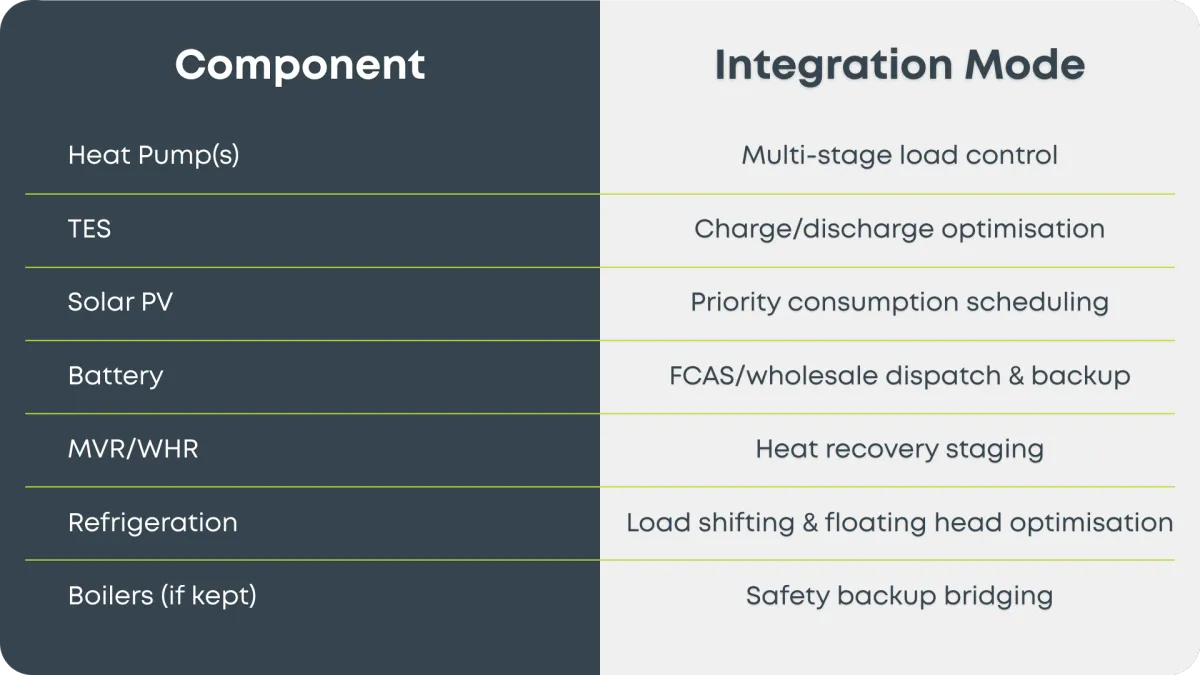

Integration Capability

We are OEM agnostic — we integrate what’s on site, not just what we sell.

Reliability & Safety

Industrial PLC with failsafe routines

Distributed control nodes where needed

Manual override capability

Blackout resilience with ride-through logic

Designed for 24/7 industrial duty, not building automation

Cyber-secure architecture